Identifying and Addressing Concrete Cracks in Columbus, Ohio

Concrete is a staple of modern construction, providing the foundation for countless buildings, roads, and infrastructure across Columbus, Ohio. However, even the most durable concrete surfaces are susceptible to cracks and other forms of deterioration over time. In the often harsh climate of Columbus, where temperature extremes, heavy rainfall, and road salt can take a toll, proactive concrete repair and maintenance become essential for preserving the integrity and longevity of these critical structures.

As a homeowner, property manager, or facility operator in Columbus, understanding the common causes of concrete cracks and the available repair solutions can help you protect your investment and maintain the aesthetic appeal of your property. In this comprehensive guide, we’ll explore the various types of concrete cracks, uncover the underlying reasons behind their formation, and dive into the proven techniques used by professional concrete repair contractors to mend fractured surfaces, restore smooth finishes, and ensure long-lasting results.

Identifying Common Types of Concrete Cracks in Columbus

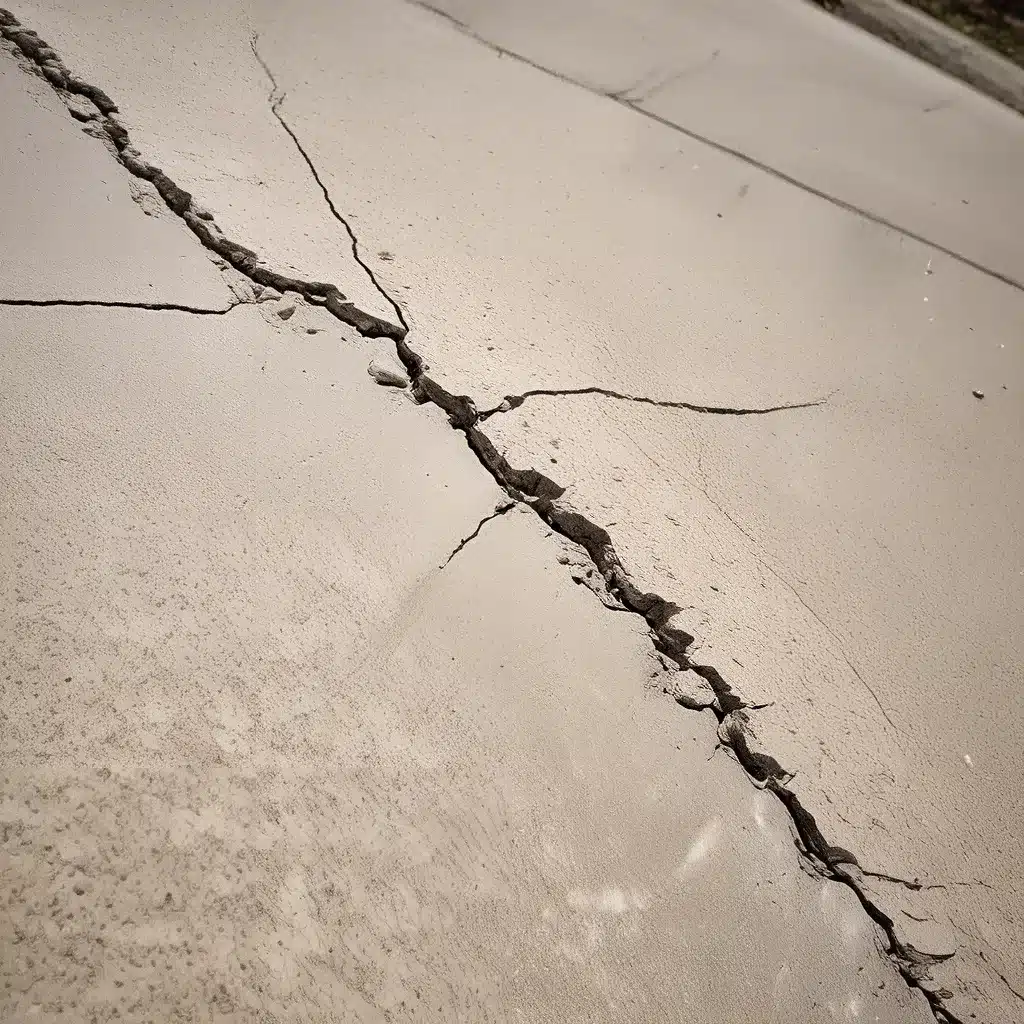

Concrete cracks can manifest in a variety of forms, each with its own unique characteristics and underlying causes. In the Columbus region, some of the most prevalent types of concrete cracks include:

Hairline Cracks: These are the most superficial type of concrete cracks, typically less than 1/8 inch in width. While they may appear cosmetic in nature, hairline cracks can still allow water infiltration and lead to more significant issues if left unaddressed.

Map Cracking: Also known as alligator cracking, this pattern of interconnected cracks resembles the scales of an alligator’s skin. Map cracking is often a sign of structural failure or subgrade instability, and it requires prompt attention to prevent further deterioration.

Shrinkage Cracks: As concrete cures and dries, it can experience volume changes that result in the formation of linear cracks, usually running perpendicular to the longest dimension of the slab or structure.

Settlement Cracks: When the soil or foundation underneath a concrete surface settles or shifts, it can lead to the development of cracks, often forming diagonal patterns or stair-step configurations.

Expansion Cracks: Caused by the expansion of concrete due to temperature changes, moisture, or the presence of reactive aggregates, these cracks typically appear in a linear or random pattern.

Reflective Cracks: These cracks occur when a concrete surface is placed over an existing cracked surface, such as an asphalt pavement. The new concrete can “reflect” the underlying crack pattern, requiring specialized repair techniques.

Understanding the unique characteristics and underlying causes of these concrete cracks is crucial for developing an effective repair strategy tailored to the specific needs of your Columbus property.

Diagnosing and Assessing Concrete Cracks in Columbus

Identifying the root cause of concrete cracks is the first step in determining the appropriate repair method. In Columbus, where environmental factors and soil conditions can significantly impact the integrity of concrete structures, a thorough assessment by a qualified concrete repair specialist is recommended.

During the assessment process, the contractor will closely examine the size, location, pattern, and depth of the cracks, as well as any accompanying signs of deterioration, such as spalling, scaling, or crumbling. They may also perform testing to evaluate the structural integrity of the concrete and identify any underlying issues with the subgrade or foundation.

By conducting a comprehensive evaluation, the concrete repair specialist can develop a tailored solution that addresses the specific challenges faced by the concrete surface in Columbus, whether it’s a residential driveway, a commercial parking lot, or a municipal sidewalk.

Repairing Concrete Cracks in Columbus

Once the root cause of the concrete cracks has been identified, the concrete repair contractor can select the most appropriate repair method to restore the surface and prevent future issues. Some of the common concrete crack repair techniques used in Columbus include:

Epoxy Injection: For narrow, structural cracks, epoxy injection is a popular and effective solution. The contractor injects a low-viscosity epoxy resin into the crack, which then hardens and bonds the concrete, restoring its strength and integrity.

Concrete Crack Sealing: For non-structural, superficial cracks, such as hairline or map cracks, the contractor may choose to seal the cracks with a flexible, elastomeric sealant. This helps prevent water infiltration and further crack propagation.

Partial-Depth Patching: In cases of spalling or shallow concrete deterioration, the contractor may remove the damaged concrete and patch the affected area with a high-performance, polymer-modified concrete mix.

Full-Depth Replacement: For severe, structural cracks or extensive concrete failure, the contractor may need to completely remove and replace the damaged section, ensuring a long-lasting, durable repair.

Surface Resurfacing: If the concrete surface has experienced widespread deterioration, the contractor may recommend a full-scale resurfacing process, which involves applying a new, high-quality concrete overlay to restore a smooth, uniform appearance.

The selection of the appropriate repair method will depend on the specific condition of the concrete, the level of damage, and the performance requirements of the surface in the Columbus environment.

Concrete Crack Repair Materials and Techniques in Columbus

When it comes to concrete crack repair in Columbus, the choice of materials and techniques can significantly impact the longevity and effectiveness of the repair. Professional concrete repair contractors in the area have access to a wide range of high-performance products and specialized equipment to ensure the best possible outcomes.

Epoxy Resins: Epoxy-based products are commonly used for structural crack repair due to their exceptional strength, durability, and adhesion to concrete. These resins can effectively seal and bond the crack, restoring the load-bearing capacity of the concrete surface.

Polyurethane Foams: For non-structural cracks or voids in the concrete, polyurethane foam injections can be an effective solution. These expanding foams can fill and seal the cracks, preventing further water infiltration and deterioration.

Polymer-Modified Concrete: When partial-depth patching is required, polymer-modified concrete mixes are often used to ensure a strong, durable, and long-lasting repair that integrates seamlessly with the surrounding concrete.

High-Performance Overlays: For extensive concrete resurfacing, specialized overlay materials, such as cementitious or epoxy-based systems, can provide a smooth, uniform finish while improving the overall strength and resistance of the concrete surface.

In addition to the materials, the application techniques used by the concrete repair contractor can also significantly impact the quality and longevity of the repair. Proper surface preparation, accurate mixing and application of the repair materials, and appropriate curing conditions are all critical factors in ensuring a successful concrete crack repair project in Columbus.

Maintaining Concrete Surfaces in Columbus

Concrete repair and maintenance is an ongoing process, especially in the challenging climate of Columbus, Ohio. Even after a successful crack repair or resurfacing project, it’s essential to implement a proactive maintenance plan to protect the investment and extend the lifespan of the concrete surface.

Regular Inspections: Conduct periodic inspections of your concrete surfaces, looking for early signs of cracking, spalling, or other deterioration. This allows you to address issues before they become more severe and costly to repair.

Concrete Sealing: Applying a high-quality concrete sealer can help protect the surface from water infiltration, chemical attack, and UV damage, reducing the risk of future cracking and deterioration.

Prompt Repair: If new cracks or damage do occur, it’s crucial to address them promptly with the help of a professional concrete repair contractor. Neglecting minor issues can lead to more extensive and expensive repairs down the line.

Proper Snow/Ice Removal: In Columbus, where harsh winters and road salt can wreak havoc on concrete surfaces, carefully removing snow and ice and using appropriate de-icing methods can help minimize the risk of cracking and spalling.

By incorporating these proactive maintenance strategies into your property management plan, you can safeguard your concrete investments, extend their lifespan, and maintain the aesthetic appeal of your Columbus property.

Conclusion: Securing the Strength and Beauty of Concrete in Columbus

Concrete is an integral part of the built environment in Columbus, Ohio, serving as the foundation for countless structures, sidewalks, and infrastructure. However, the region’s challenging climate and environmental factors can take a toll on even the most durable concrete surfaces, leading to the formation of cracks and other types of deterioration.

By understanding the common causes of concrete cracks, recognizing the various types of damage, and employing proven repair and maintenance strategies, property owners and managers in Columbus can protect their concrete investments, ensure long-lasting performance, and maintain the aesthetic appeal of their properties.

Whether you’re dealing with hairline cracks, structural failures, or widespread concrete deterioration, partnering with a reputable, experienced concrete repair contractor in Columbus can make all the difference in restoring the strength and beauty of your concrete surfaces. By taking a proactive approach to concrete maintenance, you can safeguard your property and enjoy the benefits of durable, well-maintained concrete for years to come.