The Challenges of Aging Concrete Infrastructure in Columbus, Ohio

The infrastructure of Columbus, Ohio, like many cities across the United States, is facing significant challenges as its concrete structures continue to age. According to the Federal Highway Administration, there are more than 617,000 bridges across the country, and 42% of them are at least 50 years old. In Ohio, the situation is particularly acute, with 22% of bridges considered structurally deficient, meaning they are in poor condition.

This aging infrastructure poses a serious threat to public safety and the efficient movement of goods and services. Every day, 178 million trips are taken across these structurally deficient bridges, putting countless lives at risk. The backlog of bridge repair needs in the United States is estimated at a staggering $125 billion, and the necessary annual investment to address this issue has been calculated at $227 billion – a 58% increase from current spending levels.

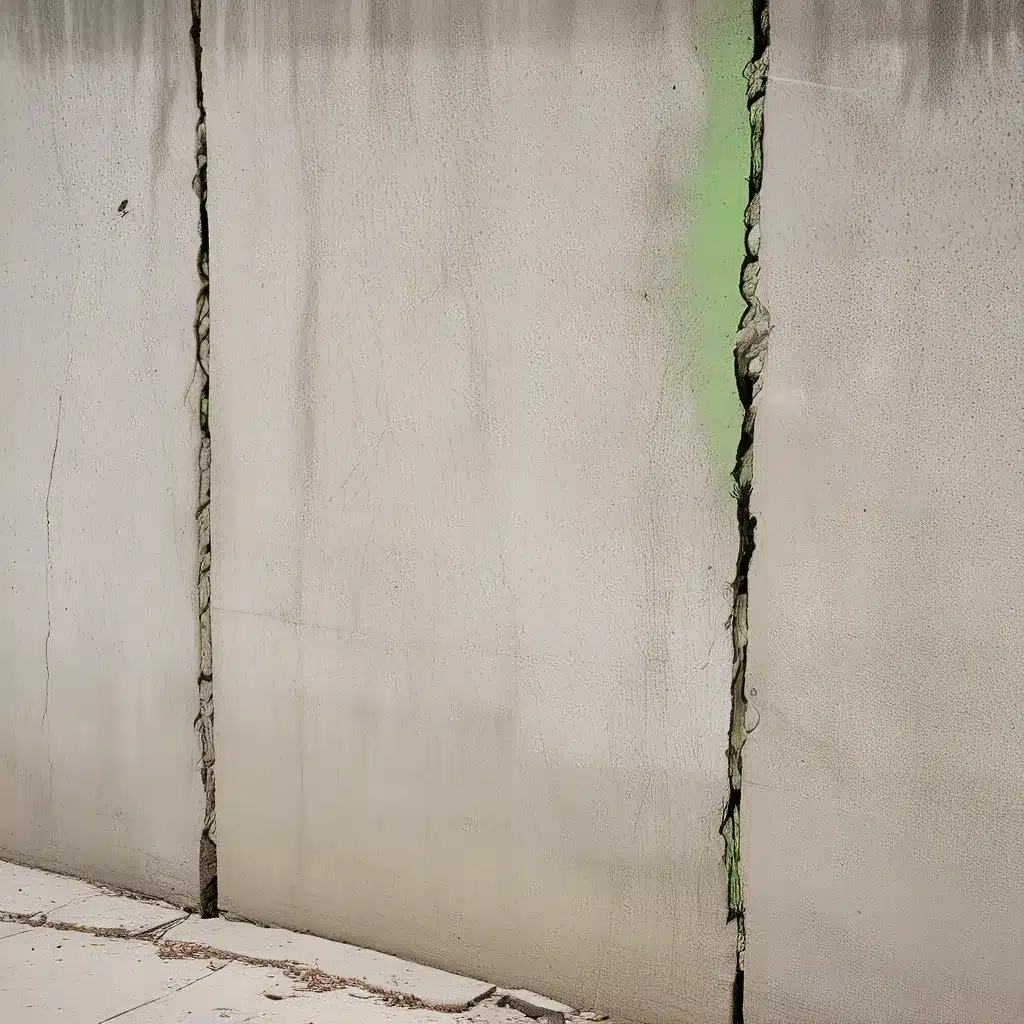

In Columbus, the situation is no different. The city’s concrete bridges, roads, and other critical infrastructure are in dire need of attention. The rate of bridge deterioration is outpacing the rate of repair, rehabilitation, and replacement, and it is estimated that it will take until 2071 to address all the necessary repairs. This is simply not a sustainable model, and it is time for a new approach.

Embracing Innovative Concrete Repair Techniques

As the concrete infrastructure in Columbus continues to age, the need for innovative repair techniques has become increasingly evident. Fortunately, the industry has made significant strides in developing new materials, technologies, and construction methods that can help extend the lifespan of concrete structures and make them more resilient.

One of the most promising innovations in the field of concrete repair is the use of ultra-high-performance concrete (UHPC). UHPC is a specialized cement-based composite material that offers superior strength, durability, and corrosion resistance compared to traditional concrete. This material can be used to repair and reinforce existing concrete structures, as well as in the construction of new bridges and buildings.

Another innovative technique is the use of corrosion-resistant reinforcement, such as stainless steel or fiber-reinforced polymer (FRP). These materials are more resistant to the effects of weathering, chemical exposure, and other environmental factors, which can help extend the lifespan of concrete structures.

In addition to new materials, the industry is also embracing advanced assessment and monitoring technologies to better understand the condition of concrete structures. Techniques like infrared thermography, ground-penetrating radar, and remotely operated drones are being used to identify problems early, prioritize repairs, and make more informed decisions about the management of concrete assets.

Sustainable Concrete Repair: Minimizing Environmental Impact

As the city of Columbus works to address its aging concrete infrastructure, it is also important to consider the environmental impact of these repair and maintenance efforts. Concrete production and construction are significant contributors to greenhouse gas emissions, and there is a growing emphasis on developing more sustainable solutions.

One way that the concrete repair industry is addressing this challenge is through the use of recycled and renewable materials. Fly ash, slag, and other industrial byproducts can be used as partial replacements for cement, reducing the carbon footprint of concrete production. Additionally, the use of bio-based polymers and natural fibers in concrete repair can further improve the environmental profile of these solutions.

Another important aspect of sustainable concrete repair is the focus on minimizing disruption and environmental disturbance during construction. Techniques like Accelerated Bridge Construction (ABC) and the use of prefabricated bridge elements can significantly reduce the amount of time that a structure is under repair, limiting the impact on the surrounding community and the environment.

Investing in Columbus’ Concrete Future

To address the challenges facing its aging concrete infrastructure, the city of Columbus must make a significant investment in repair, rehabilitation, and replacement efforts. This will require a coordinated effort between all levels of government, as well as collaboration with the private sector and the community.

At the state level, Ohio has taken steps to increase funding for infrastructure projects, including raising the gas tax to provide more resources for bridge and road maintenance. However, federal investment in the nation’s bridges remains stagnant, and more funding is needed to address the growing backlog of repair needs.

Strategic asset management will also be crucial in prioritizing and managing the city’s concrete assets. The development and implementation of Transportation Asset Management Plans (TAMPs) can help Columbus make data-driven decisions about where to allocate resources, ensuring that the most critical projects are addressed first.

By embracing innovative repair techniques, prioritizing sustainability, and investing in the long-term health of its concrete infrastructure, Columbus can set an example for cities across the country. The future of the city’s roads, bridges, and other critical structures depends on a proactive and comprehensive approach to concrete repair and maintenance.

Conclusion: Building a Resilient Concrete Future for Columbus

The challenges facing the concrete infrastructure in Columbus, Ohio, are significant, but they are not insurmountable. By leveraging the latest advancements in materials, technology, and construction methods, the city can work to extend the lifespan of its concrete structures and make them more resilient in the face of extreme weather events, heavier traffic loads, and other emerging threats.

At the same time, it is essential that Columbus takes a holistic and sustainable approach to concrete repair and maintenance. By prioritizing the use of recycled and renewable materials, minimizing environmental disturbance during construction, and investing in strategic asset management, the city can lead the way in building a more sustainable and resilient concrete future.

Through a coordinated effort between all levels of government, the private sector, and the community, Columbus can address the aging of its concrete infrastructure and ensure that its roads, bridges, and other critical structures continue to serve the needs of its residents and businesses for generations to come. The time to act is now, and the city’s commitment to innovative and sustainable concrete repair will be a key determinant of its long-term prosperity.