Weathering the Elements: Concrete Repair Solutions for Columbus’ Climate

Living in Columbus, Ohio, means dealing with a diverse range of weather conditions that can take a toll on concrete structures. From the freezing winters to the humid summers, the city’s climate presents unique challenges when it comes to maintaining and repairing concrete surfaces. As a leading provider of concrete repair services in the area, we’ve encountered a wide range of issues and developed effective solutions to help homeowners, property managers, and business owners in Columbus keep their concrete in top shape.

Combating Freeze-Thaw Cycles

One of the most significant challenges in Columbus is the freeze-thaw cycle, which can cause extensive damage to concrete over time. As temperatures fluctuate, the water in the concrete expands and contracts, leading to cracks, spalling, and other forms of deterioration. To address this issue, our team uses specialized concrete sealers and resurfacing techniques to create a protective barrier that helps prevent moisture intrusion and minimizes the impact of these temperature changes.

By applying a high-quality concrete sealer, we can create a durable, long-lasting shield that seals off the porous concrete surface, preventing water from penetrating and causing damage. This solution is particularly effective for driveways, sidewalks, and other outdoor concrete surfaces that are regularly exposed to the elements.

For more severely damaged concrete, we may recommend concrete resurfacing. This process involves removing the top layer of the concrete and applying a new, specialized concrete mix that is designed to withstand the rigors of the local climate. The result is a rejuvenated surface that is more resistant to freeze-thaw cycles, cracking, and other common concrete problems.

Addressing Surface Imperfections

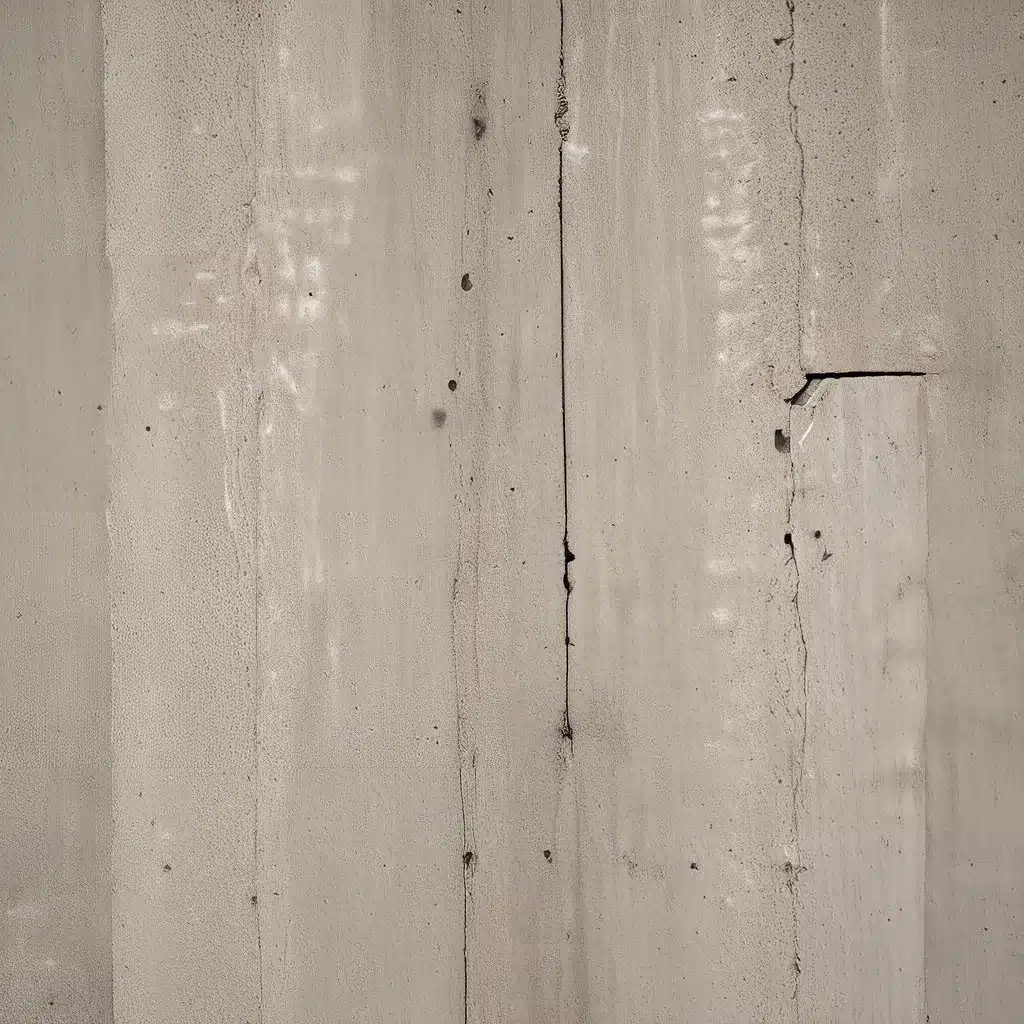

In addition to the challenges posed by the weather, concrete in Columbus can also suffer from a variety of surface imperfections, such as cracks, spalling, and discoloration. These issues can not only be unsightly but can also compromise the structural integrity of the concrete over time.

To tackle these problems, our team utilizes a range of concrete repair techniques, including crack filling, spall repair, and concrete grinding and polishing. By carefully assessing the extent and nature of the damage, we can recommend the most appropriate solution to restore the concrete’s appearance and functionality.

For example, crack filling involves using specialized epoxy or polyurethane compounds to fill and seal cracks, preventing further damage and ensuring a smooth, uniform surface. Spall repair, on the other hand, involves removing the damaged concrete and replacing it with a new, high-quality mixture, ensuring a seamless and durable finish.

In some cases, concrete grinding and polishing may be the best solution, especially for indoor concrete surfaces or high-traffic areas. This process involves mechanically removing the top layer of the concrete and then polishing it to a smooth, glossy finish, creating a visually appealing and highly durable surface.

Maintaining Concrete Surfaces

Proactive maintenance is the key to keeping concrete structures in top condition and extending their lifespan. In Columbus, where the weather can be particularly harsh, regular concrete cleaning, sealing, and resurfacing are essential for preserving the integrity of concrete surfaces.

Our team recommends a comprehensive maintenance plan that includes:

- Concrete cleaning: Regularly cleaning the concrete to remove dirt, debris, and any buildup that can lead to damage over time.

- Concrete sealing: Applying a high-quality sealer to protect the concrete from the elements and prevent moisture intrusion.

- Concrete resurfacing: Periodically resurfacing the concrete to address any wear and tear and restore its appearance and performance.

By following this maintenance routine, property owners in Columbus can ensure that their concrete surfaces remain in excellent condition, minimizing the need for costly repairs and preserving the long-term value of their investments.

Addressing Unique Concrete Challenges in Columbus

In addition to the weather-related issues, concrete in Columbus may also face other challenges, such as chemical spills, oil stains, and heavy loading. Whether it’s a commercial property, an industrial facility, or a residential driveway, our team has the expertise to tackle these specialized concrete repair and maintenance needs.

For chemical spills or oil stains, we utilize specialized cleaning and degreasing techniques to remove the contaminants and restore the concrete’s appearance and structural integrity. In cases of heavy loading, such as in warehouses or manufacturing plants, we can recommend reinforced concrete solutions or joint sealants to ensure the concrete can withstand the increased stress and strain.

By staying up-to-date with the latest industry trends and best practices, we are able to provide our clients in Columbus with comprehensive concrete repair and maintenance solutions that address their unique challenges and needs.

Partnering with Concrete Repair Experts in Columbus

Maintaining and repairing concrete in Columbus requires a deep understanding of the local climate, as well as a commitment to using the right materials and techniques. At Concrete Repair Columbus Ohio, our team of experienced professionals has been serving the community for years, helping homeowners, property managers, and business owners keep their concrete surfaces in top condition.

Whether you’re dealing with the effects of freeze-thaw cycles, surface imperfections, or specialized concrete challenges, we have the knowledge and expertise to provide a tailored solution that meets your needs and budget. Contact us today to learn more about our concrete repair services and how we can help you maintain the integrity and appearance of your concrete structures in Columbus.

Exploring the Science Behind Concrete Repair

Concrete is a ubiquitous building material that is used in a wide range of applications, from residential driveways to commercial high-rises. While it is known for its durability and strength, concrete is not immune to the effects of weathering, wear and tear, and other environmental factors. Understanding the science behind concrete repair is essential for ensuring the longevity and performance of concrete structures in Columbus.

The Composition and Structure of Concrete

Concrete is a composite material made up of three primary components: cement, aggregates, and water. The cement, typically a Portland cement, acts as the binding agent, while the aggregates (such as sand, gravel, or crushed stone) provide the bulk and structure. When the cement and water are mixed, a chemical reaction called hydration occurs, causing the mixture to harden and form a solid, durable material.

The microstructure of concrete is a crucial factor in its performance and durability. As the cement hydrates, it forms a calcium-silicate-hydrate (C-S-H) gel, which is the primary binding agent in concrete. The arrangement and density of the C-S-H gel, as well as the distribution and size of the aggregates, can have a significant impact on the concrete’s strength, permeability, and resistance to various forms of deterioration.

Common Concrete Repair Challenges

One of the most common challenges in concrete repair is cracking, which can occur due to a variety of reasons, including:

- Shrinkage: As the concrete dries and cures, it can shrink, leading to the formation of cracks.

- Thermal expansion and contraction: Temperature changes can cause the concrete to expand and contract, leading to the development of cracks.

- Structural loading: Excessive weight or stress on the concrete can cause it to crack or spall (flake or chip).

Another common issue is spalling, which refers to the flaking or chipping of the concrete surface. Spalling can be caused by a variety of factors, including freeze-thaw cycles, chemical attack, and reinforcement corrosion.

Discoloration and staining can also be a concern, as concrete can be affected by various environmental factors, such as oil and chemical spills, efflorescence (the white, powdery substance that can form on the surface), and weathering.

Concrete Repair Techniques and Materials

To address these challenges, concrete repair professionals in Columbus employ a variety of techniques and materials, including:

- Crack Repair: Involves the use of epoxy or polyurethane resins to fill and seal cracks, restoring the structural integrity of the concrete.

- Spall Repair: Involves the removal of the damaged concrete and the application of a new, specialized concrete mixture to restore the surface.

- Concrete Resurfacing: Involves the application of a thin layer of new concrete or specialized resurfacing materials to address surface imperfections and restore the appearance of the concrete.

- Concrete Sealing: Involves the application of a protective coating, such as a concrete sealer or concrete stain, to prevent moisture intrusion, freeze-thaw damage, and other environmental factors.

- Concrete Grinding and Polishing: Involves the mechanical removal of the top layer of the concrete and the polishing of the surface to create a smooth, glossy finish.

The selection of the appropriate repair technique and materials depends on the severity and type of the concrete damage, as well as the specific requirements of the project, such as traffic load, aesthetic considerations, and budget.

The Importance of Proper Concrete Repair in Columbus

Proper concrete repair is essential for maintaining the structural integrity, appearance, and longevity of concrete structures in Columbus. By understanding the science behind concrete and the challenges specific to the local climate, concrete repair professionals can develop tailored solutions that address the unique needs of property owners and ensure the long-term performance of their concrete surfaces.

At Concrete Repair Columbus Ohio, our team of experts is committed to staying up-to-date with the latest research and best practices in the industry, enabling us to provide our clients with the most effective and durable concrete repair solutions. Contact us today to learn more about how we can help you protect your investment and maintain the integrity of your concrete structures in Columbus.

Navigating the Complexities of Concrete Resurfacing

One of the most effective ways to address the deterioration of concrete surfaces in Columbus is through concrete resurfacing. This process involves removing the top layer of the existing concrete and applying a new, specialized concrete mixture to create a fresh, rejuvenated surface. Concrete resurfacing can be a valuable solution for a variety of concrete challenges, from cracking and spalling to discoloration and uneven surfaces.

Understanding the Concrete Resurfacing Process

The concrete resurfacing process typically involves the following steps:

- Surface Preparation: The existing concrete surface is thoroughly cleaned and any cracks, spalls, or other imperfections are repaired using specialized concrete repair materials.

- Concrete Removal: The top layer of the concrete is mechanically removed, typically using a concrete grinder or scarifier, to create a roughened surface that will provide a strong bond for the new concrete overlay.

- Concrete Overlay Application: A new, specialized concrete mixture is applied to the prepared surface, creating a seamless, uniform finish that matches the existing concrete or can be customized to meet specific aesthetic or performance requirements.

- Curing and Finishing: The new concrete overlay is allowed to cure and then, if desired, can be polished or sealed to enhance its appearance and durability.

The key to successful concrete resurfacing is the selection of the appropriate concrete mixture and the proper execution of each step in the process. This requires a deep understanding of concrete science, as well as practical experience in dealing with the unique challenges of the Columbus climate.

Benefits of Concrete Resurfacing in Columbus

Concrete resurfacing offers a range of benefits for property owners in Columbus, including:

- Restoration of Appearance: Resurfacing can transform an aging, unsightly concrete surface into a fresh, visually appealing one, adding to the overall aesthetic of the property.

- Improved Durability: The new concrete overlay is designed to be more resistant to weathering, cracking, and other forms of deterioration than the original concrete, ensuring long-lasting performance.

- Enhanced Safety: Resurfacing can create a smoother, more level surface, reducing the risk of tripping hazards and improving accessibility for pedestrians and vehicles.

- Increased Property Value: By restoring the condition and appearance of concrete surfaces, resurfacing can increase the overall value of a property, making it a wise investment for homeowners and commercial property owners alike.

Concrete Resurfacing Considerations in Columbus

When considering concrete resurfacing in Columbus, there are a few key factors to keep in mind:

- Climate Suitability: The concrete mixture used for resurfacing must be formulated to withstand the region’s freeze-thaw cycles and other environmental stresses**.

- Surface Preparation: Proper surface preparation is essential for ensuring a strong bond between the existing concrete and the new overlay, which is critical in Columbus’ harsh climate.

- Aesthetic Preferences: Concrete resurfacing offers a wide range of customization options, from color and texture to patterns and finishes, allowing property owners to tailor the appearance to their specific needs and preferences.

- Cost Considerations: The cost of concrete resurfacing can vary depending on the size of the project, the complexity of the surface preparation, and the desired finish, but it is often a cost-effective solution compared to complete concrete replacement.

By working with experienced concrete repair professionals in Columbus, property owners can ensure that their concrete resurfacing project is executed with the utmost care and attention to detail, resulting in a durable, long-lasting, and visually appealing concrete surface.

Uncovering the Secrets of Effective Concrete Sealing

Keeping concrete surfaces in top condition is a constant challenge for property owners in Columbus, Ohio, where the harsh weather conditions and heavy use can take a significant toll. One of the most effective ways to protect and preserve concrete is through the application of high-quality concrete sealers. These specialized coatings can help to prevent moisture intrusion, mitigate the effects of freeze-thaw cycles, and enhance the overall appearance of concrete surfaces.

Understanding the Benefits of Concrete Sealing

Concrete sealing offers a range of benefits for property owners in Columbus, including:

- Moisture Protection: Concrete sealers create a barrier that prevents water and other liquids from penetrating the concrete, reducing the risk of cracking, spalling, and other forms of deterioration.

- Freeze-Thaw Resistance: By sealing the concrete surface, sealers can minimize the impact of the region’s freeze-thaw cycles**, which are a leading cause of concrete damage in Columbus.

- Surface Enhancement: Many concrete sealers can enhance the appearance of the concrete, improving the color and providing a glossy or matte finish that complements the property’s aesthetics.

- Increased Durability: Properly sealed concrete is more resistant to abrasion, chemical attack, and other forms of wear and tear**, ensuring a longer lifespan for the concrete surface.

Choosing the Right Concrete Sealer for Columbus

When it comes to concrete sealing in Columbus, not all sealers are created equal. Different types of concrete sealers are designed to address specific challenges and performance requirements, so it’s essential to select the right product for the job.

Some of the most common types of concrete sealers used in Columbus include:

- Acrylic Sealers: These water-based or solvent-based sealers provide a clear, glossy finish and offer good protection against UV damage and moderate wear and tear**.

- Epoxy Sealers: Two-part epoxy sealers offer exceptional durability and chemical resistance, making them a popular choice for industrial and commercial applications.

- Polyurethane Sealers: Polyurethane sealers combine the toughness of epoxy with the flexibility of acrylic, creating a durable, long-lasting finish that is resistant to abrasion and weathering.

- Silicone-Based Sealers: Silicone-based sealers penetrate deeply into the concrete, providing a breathable barrier that helps to prevent moisture intrusion and reduce the risk of efflorescence.

The selection of the appropriate sealer for a particular project in Columbus will depend on factors such as the concrete’s condition, the level of foot or vehicle traffic, and the desired aesthetic outcome.

Proper Concrete Sealing Techniques

Applying a concrete sealer is not a simple task; it requires careful preparation and attention to detail to ensure the best possible results. At Concrete Repair Columbus Ohio, our team of experienced professionals follows a comprehensive process to ensure the long-term success of concrete sealing projects in the Columbus area:

- Surface Preparation: The concrete surface is thoroughly cleaned to remove any dirt, debris, or contaminants that could interfere with the sealer’s adhesion.

- Sealer Application: The sealer is