The Art and Science of Concrete Repair

In the bustling city of Columbus, Ohio, where the skyline stands testament to human ingenuity and progress, the unsung heroes of concrete repair quietly toil to preserve the structural integrity of the built environment. From towering skyscrapers to humble sidewalks, the challenges posed by cracked, spalled, or deteriorating concrete demand the expertise of skilled professionals who can unleash the power of cutting-edge techniques and materials.

As the heartbeat of the Midwest, Columbus is no stranger to the relentless forces of weathering, aging, and environmental stresses that can wreak havoc on concrete structures. Whether it’s the scorching summer heat, the biting winter chill, or the occasional bout of heavy rainfall, the city’s concrete foundations are constantly put to the test. Maintaining the longevity and safety of these vital elements is a critical task that requires a deep understanding of the science behind concrete composition and the art of effective repair.

Concrete Repair Columbus Ohio professionals have honed their skills over years of experience, tackling a diverse array of concrete repair projects across the city. From repairing cracks in a busy commercial parking lot to restoring the structural integrity of a historic landmark, their expertise encompasses a wide range of techniques and solutions.

The Science of Concrete Repair

At the core of successful concrete repair lies a deep appreciation for the material’s unique properties and behavior. Concrete, a composite material made up of cement, aggregates, water, and various admixtures, is known for its exceptional compressive strength, but it can also be susceptible to tensile and shear stresses that can lead to cracking and degradation over time.

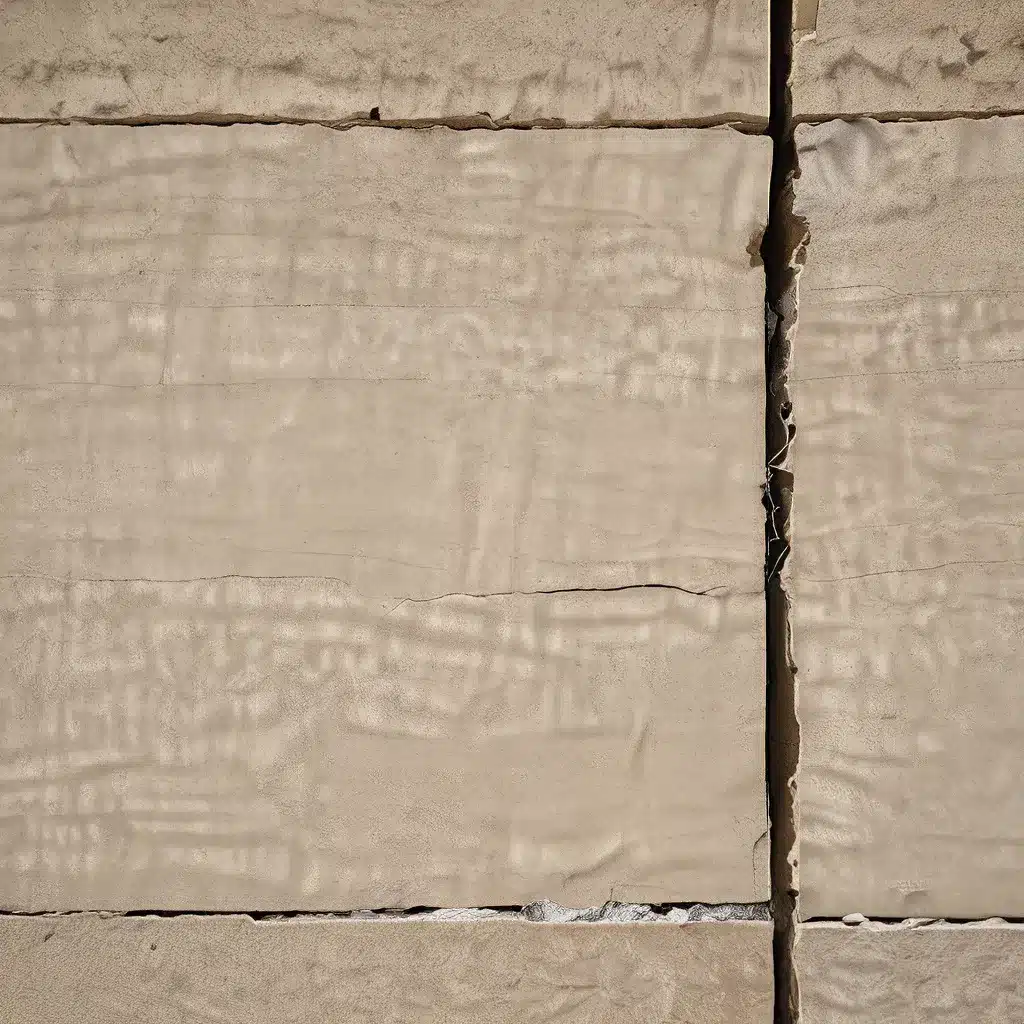

One of the primary causes of concrete deterioration in Columbus is the freeze-thaw cycle, a phenomenon that occurs when water seeps into the porous material and expands upon freezing. This expansion can create significant stresses within the concrete, leading to the formation of cracks and spalling, where pieces of the surface break off. Additionally, chemical attacks, such as exposure to de-icing salts or acidic environments, can further exacerbate the deterioration process.

To effectively address these challenges, concrete repair specialists in Columbus employ a range of innovative techniques and materials. Epoxy injection, for instance, is a popular method for sealing and repairing cracks, as the epoxy resin forms a strong, durable bond with the surrounding concrete. Concrete overlays, on the other hand, can be used to resurface deteriorated concrete surfaces, providing a fresh, protective layer that enhances the structure’s appearance and durability.

The Art of Concrete Repair

While the science behind concrete repair is fundamental, the true mastery lies in the art of applying these techniques with precision and care. Skilled concrete repair professionals in Columbus understand that each project is unique, with its own set of site-specific conditions, accessibility challenges, and aesthetic considerations.

Effective concrete repair begins with a meticulous assessment of the problem at hand. Inspecting the concrete surface, identifying the root causes of the deterioration, and determining the appropriate course of action are critical first steps. This process often involves a combination of visual inspection, non-destructive testing, and laboratory analysis to ensure a comprehensive understanding of the concrete’s condition.

Once the diagnosis is complete, the repair team can begin the delicate process of executing the necessary interventions. This may involve surface preparation, such as sandblasting or hydrodemolition to remove any loose or damaged material, before applying the chosen repair solution. The art of concrete repair also encompasses the careful selection and application of specialized materials, ensuring a seamless and visually appealing final result that blends harmoniously with the surrounding environment.

Concrete Repair Techniques for Columbus Conditions

Given the unique climate and environmental factors that impact concrete structures in Columbus, the city’s concrete repair professionals have developed a deep understanding of the most effective techniques for addressing the region’s specific challenges.

Epoxy Injection for Crack Repair

One of the go-to solutions for repairing cracks in concrete in Columbus is epoxy injection. This process involves injecting a high-strength epoxy resin into the affected areas, effectively sealing the cracks and restoring the structural integrity of the concrete. Epoxy injection is particularly well-suited for addressing hairline cracks or wider cracks that may have developed due to thermal expansion, settlement, or other stresses.

Concrete Overlays for Resurfacing

When faced with deteriorated or spalled concrete surfaces, Columbus repair specialists often turn to concrete overlays as a solution. These thin, durable coatings can be applied directly over the existing concrete, providing a fresh, protective layer that enhances both the appearance and the longevity of the structure. Concrete overlays are especially useful for addressing uneven or crumbling sidewalks, driveways, and parking lot surfaces.

Corrosion Mitigation Strategies

In areas where reinforced concrete is exposed to corrosive elements, such as de-icing salts or industrial chemicals, concrete repair professionals in Columbus employ specialized corrosion mitigation strategies. This may involve applying a protective coating to the concrete surface, replacing corroded rebar, or using cathodic protection systems to prevent further deterioration.

Weatherproofing and Sealants

To combat the effects of weathering and environmental stresses on concrete structures in Columbus, repair experts often utilize weatherproofing and sealant solutions. These include waterproofing membranes, joint sealants, and concrete sealers that create a barrier against moisture intrusion, UV radiation, and other damaging elements.

By combining their deep understanding of concrete science with the artistry of effective repair techniques, Columbus concrete repair professionals are able to restore and preserve the structural integrity of the city’s built environment, ensuring the safety and longevity of the structures that serve as the foundation of the community.

Maintaining Concrete Structures in Columbus

Preventing the need for extensive concrete repair in Columbus requires a proactive approach to regular maintenance and inspections. Homeowners, property managers, and commercial building owners should establish a routine schedule for inspecting concrete surfaces, identifying any signs of deterioration, and addressing them promptly before they escalate.

Regular cleaning and sealing of concrete surfaces can go a long way in protecting them from the ravages of weathering and environmental stresses. Power washing, applying concrete sealers, and addressing any cracks or spalling in a timely manner can significantly extend the lifespan of concrete structures and reduce the need for major repair interventions down the line.

For those faced with more complex concrete repair challenges, it is crucial to enlist the expertise of experienced, licensed, and insured concrete repair professionals in the Columbus area. These specialists can provide a comprehensive assessment, develop a tailored repair plan, and execute the necessary work with the utmost care and attention to detail, ensuring the long-term durability and safety of the concrete structures that are so vital to the city’s infrastructure.

By embracing the science and art of concrete repair, the dedicated professionals in Columbus are empowered to tackle the most complex challenges, restoring the structural integrity of the city’s built environment and preserving the foundations that support its vibrant community.